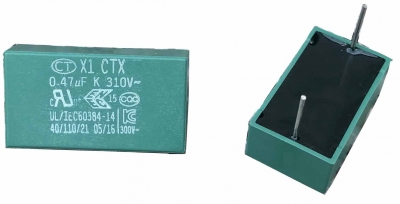

X1 310VAC FLAT

Product Introduction

SPECIFICATION

ACROSS-THE-LINE AND INTERFERENCE SUPPRESSION CAPACITOIR CLASS X1 --- CTX

- REFERENCE STANDARDS: UL 60384-14, CSA C22.2

USED FOR ACROSS-THE LINE CAPACITORS, ANTENNA-COUPLING AND LINE-BY-PASS COMPONENTS.

ENEC EN (IEC) 60384-14 (ed.4)2013

KC Mark K60384-14

USED FOR RADIO INTERFERENCE SUPPRESSION CAPACITORS.

- RATED VOLTAGE : 310 VAC, 50 ~ 60 Hz

- CAPACITANCE RANGE : 0.1 μF ~ 0.47μF

- CAPACITANCE TOLERANCE : J (±5﹪), K (±10﹪), M (±20﹪), U (+10-5﹪)

- DIELECTRIC : METALLIZED POLYPROPYLENE FILM (COATING MATERIALS:Al-Zn)

- DISSIPATION FACTOR TAN δ : LESS THAN 0.1﹪ AT 1K Hz/20 ℃

VOLTAGE 1.0 VAC (CAPACITANCE : 1K Hz/20 ℃, VOLTAGE 1.0 VAC)

- INSULATION RESISTANCE : BETWEEN TERMINALS

(1) LESS THAN OR EQUAL TO 0.33 μF ≧ 3 x 104 MΩ

(2) GREATER THAN 0.33 μF ≧ 1 x 104 MΩ/μF

MEASURED AT 100 ± 15 VDC, 60 Sec./20 ℃

- 8. WITHSTAND VOLTAGE :

a) BETWEEN TERMINALS…. 1333VDC FOR 60 Sec. OR 1700V.DC FOR 1Sec.

CUT-OFF CURRENT :10mA

b) BETWEEN TERMIANLS AND CASE….2120 VAC 60 Hz FOR 60 Sec.

9. CLIMATIC CATEGORY : IN ACCORDANCE WITH DIN 40040 GLF

G (MINIMUM LIMIT TEMPERATURE) = - 40 ℃

L (MAXIMUM LIMIT TEMPERATURE) = + 110 ℃

F (HUMIDITY CATEGORY) = AVERAGE RELATIVE HUMIDITY ≦ 75﹪

95﹪ FOR 30 DAYS PER YEAR CONTINUOSLY

85﹪ FOR THE REMAINING DAYS OCCASIONALLY

SPECIFICATION

10. DRY HEAT RESISTANCE :

IN ACCORDANCE WITH DIN 40046 SHEET 1 OR IEC 68-2-2 TEST BA.CONDITIONS

TEST TEMPERATURE : 110 ± 2 ℃

TEST DURATION : 16 HOURS

TEST CRITERIA :

(1) APPEARANCE : NO VISIBLE DAMAGE AND NO LEAKAGE

(2) WITHSTAND VOLTAGE : RATED WITHSTAND VOLTAGE 60 Sec.

(3) CAPACITANCE CHANGE : ≦±5﹪ OF THE INITIAL VALUE

(4) INSULATION RESISTANCE : ≧50﹪OF INITIAL SPECIFIED VALUE

11. COLD RESISTANCE :

IN ACCORDANCE WITH DIN 40046 SHEET 1 OR IEC 68-2-1 TEST BA. CONDITIONS

TEST TEMPERATURE : -40 ± 2 ℃

TEST DURATION : 2 HOURS

TEST CRITERIA :

(1) APPEARANCE : NO VISIBLE DAMAGE

(2) WITHSTAND VOLTAGE : RATED WITHSTAND VOLTAGE 60 Sec.

(3) CAPACITANCE CHANGE : ≦ ± 5 ﹪ OF THE INITIAL VALUE

12. HUMIDITY TEST CONDITIONS :

TEST TEMPERATURE : 40 ℃ ± 2 ℃

RELATIVE HUMIDITY : 90 – 95 ﹪

TEST DURATION : 500 HOURS

TEST CRITERIA :

(1) WITHSTAND VOLTAGE : RATED WITHSTAND VOLTAGE 60 Sec.

(2) CAPACITANCE DRIFT : ≦ ± 5 ﹪OF THE INITIAL VALUE

(3) DISSIPATION FACTOR : ≦0.8 ﹪ OF INCREASED VALUE

(4) INSULATION RESISTANCE : ≧50 ﹪OF INITIAL SPECIFIED VALUE

SPECIFICATION

13. LIFE TEST CONDITIONS :

TEST TEMPERATURE : 110 ℃ ± 3 ℃

TEST VOLTAGE : 388 VAC AND 1,000 VAC/60 HZ FOR A PERIOD OF 0.1 Sec. ONCE

EACH HOUR

TEST DURATION : 1,000 HOURS

TEST CRITERIA :

(1) APPEARANCE : NO VISIBLE DAMAGE AND NO LEAKAGE

(2) WITHSTAND VOLTAGE : RATED WITHSTAND VOLTAGE 60 Sec.

(3) CAPACITANCE DRIFT : ≦ ±10 ﹪OF THE INITIAL VALUE

(4) DISSIPATION FACTOR : ≦ 0.8 ﹪ OF INCREASED VALUE

(5) INSULATION RESISTANCE : ≧ 50 ﹪OF SPECIFIED VALUE

- 14. SOLDERABILITY CONDITIONS :

SOLDER BATH TEMPERATURE & MATERIAL :

230 ± 5 ℃, 60 ﹪OF TIN (Sn) +40 ﹪OF LEAD (Pb)

SOLDER BATH TEMPERATURE & MATERIAL :

270 ± 5 ℃, 99.96 ﹪OF TIN (Sn) +0.04 ﹪OF SILVER (Ag)

SOLDER TIME : 3 ± 0.5 Sec. TEST CRITERIA :75% OF THE SURFACE TINNING

- 15. SOLDERING HEAT RESISTANCE :

IN ACCORDANCE WITH DIN 40046 SHEET 18 OR IEC 68-2-20 TEST TA.1&TB.1

CONDITIONS

SOLDER BATH TEMPERATURE : 260 ± 5 ℃

SOLDER TIME : 4 Sec.

CAPACITANCE BODY MAY LIE ON PRINTING CIRCUIT BOARD

TEST CRITERIA :

(1) APPEARANCE : NO DAMAGE AND GOOD TINNING

(2) CAPACITANCE CHANGE : ≦ ± 3 ﹪OF THE INITIAL VALUE

- 16. VIBRATION RESISTANCE :

IN ACCORDANCE WITH DIN 40046 SHEET 8 OR IEC 68-2-6 TEST FC CONDITIONS

FREQUENCERANGE : 10 - 55 HZ

DISPLACEMENT AMPLITUDE : 0.75 mm

CONFORMING TO MAX. : 10 g

SPECIFICATION

TEST DURATION : 6 HOURS

TEST CRITERIA :

(1) APPEARANCE : NO VISIBLE DAMAGE

(2) CAPACITANCE CHANGE : ≦ ± 2 ﹪ OF THE INITIAL VALUE

17. TENSILE STRENGTH OF TERMINALS

IN ACCORDANCE WITH DIN 40046 SHEET 19 OR IEC 68-2-21 TEST UA.1

CONDITIONS

TERMINAL LOAD FORCE HOLDING TIMES

DIA. (mm) KG (N) Sec.

≦0.5 0.5 (5) 10

>0.5 TO <0.8 1.0 (10) 10

>0.8 2.0 (20) 20

TEST CRITERIA : NO WIRE BREAKAGE AND NO DAMAGE OF CAPACITOR

18. BENDING OF TERMINALS

IN ACCORDANCE WITH DIN 40046 SHEET 19 OR IEC 68-2-21 TEST UB. CONDITIONS

LOAD FORCE : 0.5 KG (5N)

BENDING TIME : TWO CONSECUTIVE BENDS (4 x 90 ℃)

TEST CRITERIA : NO WIRE BREAKAGE AND DAMAGE OF CAPACITOR

- APPROVED BY :

UL、CUL FILE NO. E193049 (0.0047uF/310V~10uF/310V)

ENEC Licence No. ENEC-01396-A1-M2(0.0047uF/310V~10uF/310V)

KC MARK HU03009-5003B (0.1uF 300V.AC)

HU03009-5001C (0.15uF 0.22uF 0.33uF 300V.AC)

HU03009-5002B (0.47uF 0.68uF 1.0uF 300V.AC)

CQC Number CQC03001008997 (0.0047~10uF 310V.AC)

TEL :

TEL :  FAX :

FAX :  Add :No.88, Ruiyuan St., Bade Dist., Taoyuan City 334, Taiwan (R.O.C.)

Add :No.88, Ruiyuan St., Bade Dist., Taoyuan City 334, Taiwan (R.O.C.) E-mail :

E-mail :  連絡人 : 沈銀鳳/彭淳欣/蘇逸凱/劉燕

連絡人 : 沈銀鳳/彭淳欣/蘇逸凱/劉燕